ISA-CP CERAMIC PASTE

ISA, Insulation Specialties of America, Inc., introduces a high temperature resistant ceramic paste for the Aluminum Industry. ISA-CP features excellent insulation properties, thermal shock resistance, molten metal resistance and ease of installation.

Ralph Searle, Sales Manager of Insulation Specialties of America, is pleased to introduce ISA-CP Ceramic Paste after extensive plant trials and field testing. ISA-CP Ceramic Paste is a great addition to ISA’s growing family of ceramic products and solutions for the aluminum industry.

ISA-CP Ceramic Paste contains a sticky, water-based refractory binder with ceramic fibers which allows the product to be easily applied by caulking, troweling, or hand forming. It is the proven choice for a wide range of application problems such as, flame impingement, erosion, and hard to insulate areas. ISA-CP Ceramic Paste possesses high temperature and thermal shock resistance, along with excellent insulation properties. It can be applied in thin cross sections without slumping, eliminating the need to install in layers. ISA-CP Ceramic Paste, when air dried, becomes hard, strong and erosion resistant. In addition, it contains inhibitors making it resistant to the reactive and wetting effects of molten aluminum and its various alloys. Sites testing the ISA-CP Ceramic Paste have given positive feedback as to this material being a new industry leader.

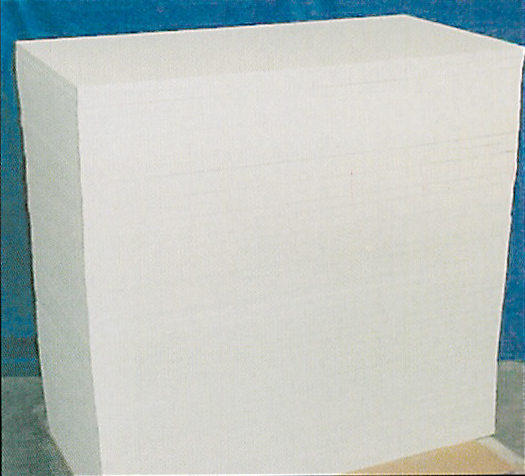

BOARDS

Our standard board sizes are 24" x 36", 24" x 48", 36" x 48", and 48" x 48" as well as specialty sizes upon request. We will custom machine boards to your specific size and surface finish. Our boards range in thickness from W' to 8" and can be made in most of our formulations. We will make your order to the temperature, thickness, and finishing specification that you request.

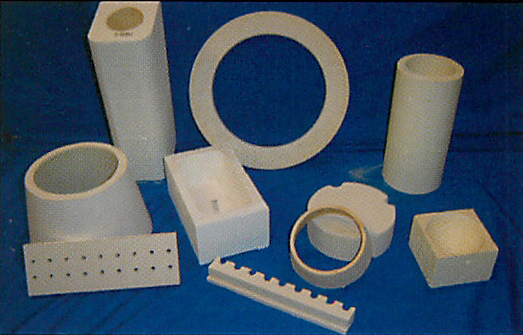

Metal Industry

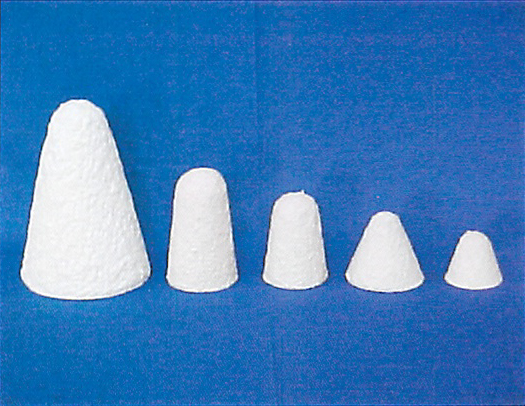

- Tap Hole Cones

- Starter Tubes

- Gaskets

- Ladle Liners

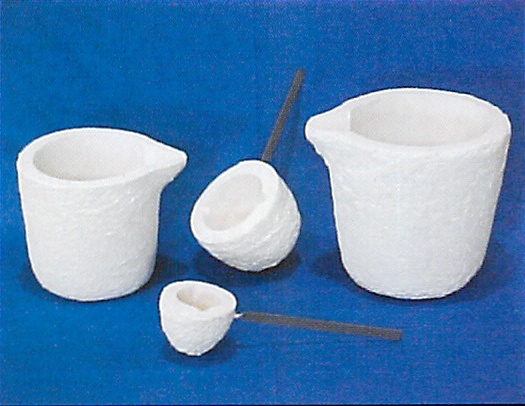

- Batch Testing Ladles

- Hot Tops

Heating Industry

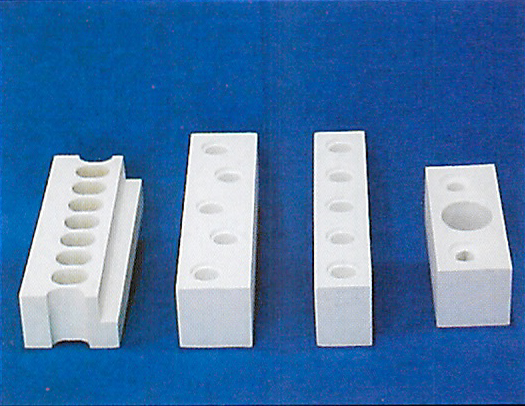

- Burner Blocks

- Flame Shields

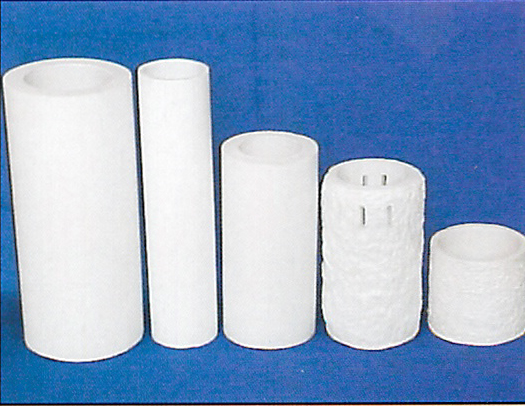

- Sleeves

- Flue Sleeves

- Combustion Chambers

- Furnace Doors

Industrial Furnaces/Kilns

- Insulating Boards

- Large Sleeves

- ISADucts and Tees

- Burner Blocks

- Sight Ports

Glass and Ceramics Industry

- Roll Blocks

- Thick Boards

- Special Shapes

- Burner Tubes

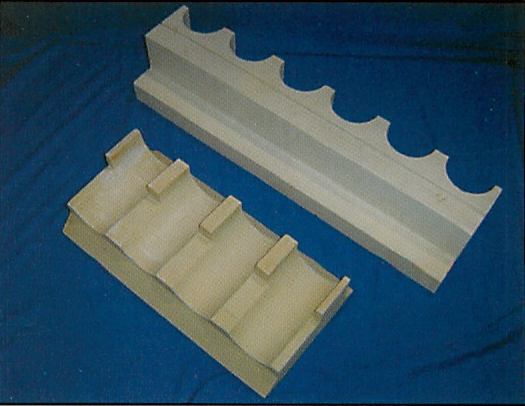

ISAFORM PRODUCT INFORMATION

ISAFORM boards and shapes are lightweight high temperature Refractory Ceramic Fiber (RCF) and Non-RCF products manufactured using ISA's vacuum forming process. All I SA FORM products offer low thermal conductivity, high temperature stability, uniform density, as well as excellent resistance to chemical attack and thermal shock. The versatility of the I SAFORM product lines allow ISA to satisfy all of your high temperature insulation needs economically and efficiently.

ISAFORM CB BOARD

ISAFORM CB is an economical solution for insulation requirements when the maximum use temperature does not exceed 2000°F. This blend of Mineral Wool Fibers and RCF has a typical density range of 12-20 pcf, making this material an excellent choice for back-up insulation as well as many other applications.

ISAFORM LD

Available in temperature grades ranging from 2300°F - 3000°F with uniform densities from 14-18 pcf. The LD products possess excellent compressibility characteristics and are commonly used when forming complex shapes as well as boards.

ISAFORM MD

Available in temperature grades ranging from 2300°F - 3000°F with uniform densities from 18-23 pcf. The MD products due to the slightly higher density are commonly used when the application calls for drilling, shiplap joints, or any other secondary machining operation.

ISAFORM HD

Available in temperature grades ranging from 2300°F - 3000°F with uniform densities from 24-29 pcf. The HD products are most commonly used when high strength, high gas I air velocities, and/or high resistance to erosion are called for in the application.

ISAFORM SHD

Super High Density boards and flat shapes are available in the 2300°F temperature formulation and the typical density range is between 35-45 pcf. SHD products are used in applications where greater strength and resistance to erosion are necessary.

ISAFORM LO

LO is available in 2300°F with uniform densities from 14-22 pcf. The LO products are produced using a low organic binder formulation, which gives the parts greater strength after firing to elevated temperatures when compared to most ACF formulations. LO products are commonly used for applications involving molten metal contact and when limited off gassing is required.

ISAFORM NCF

ISA FORM NCF (Non Ceramic Fiber) is available in both 2000°F and 2300°F temperature grades with typical densities ranging from 14-18 pcf. Both material types comply with the European Regulatory requirements for high temperature refractories.

ISAGLUE

This high temperature refractory cement is available in 2300° F. ISAGLUE is a very versatile material with uses ranging from bonding ACF parts together to repairing cracks in refractories, along with countless other uses.

ISAMOLDABLE RCF 2300

This 2300°F refractory moldable, with its putty-like consistency, permits application by caulking, troweling, and/or hand forming. Upon completion of drying, the material possesses excellent green strength in addition to superior resistance to molten aluminum.

RCF COATING CEMENT

ACF Coating Cement has a 2300° F temperature grade rating. The consistency of the cement coating makes it very versatile and provides a range of applications such as brushing, dipping, spraying, etc ... The coating once dry possesses good adhesion to most materials, erosion resistance, thermal reflectance, and resists wetting by many nonferrous molten metals.